Salmon Processing

Vélfag offers specialized salmon processing equipment, including high-yield salmon filleting machines and efficient heading solutions.

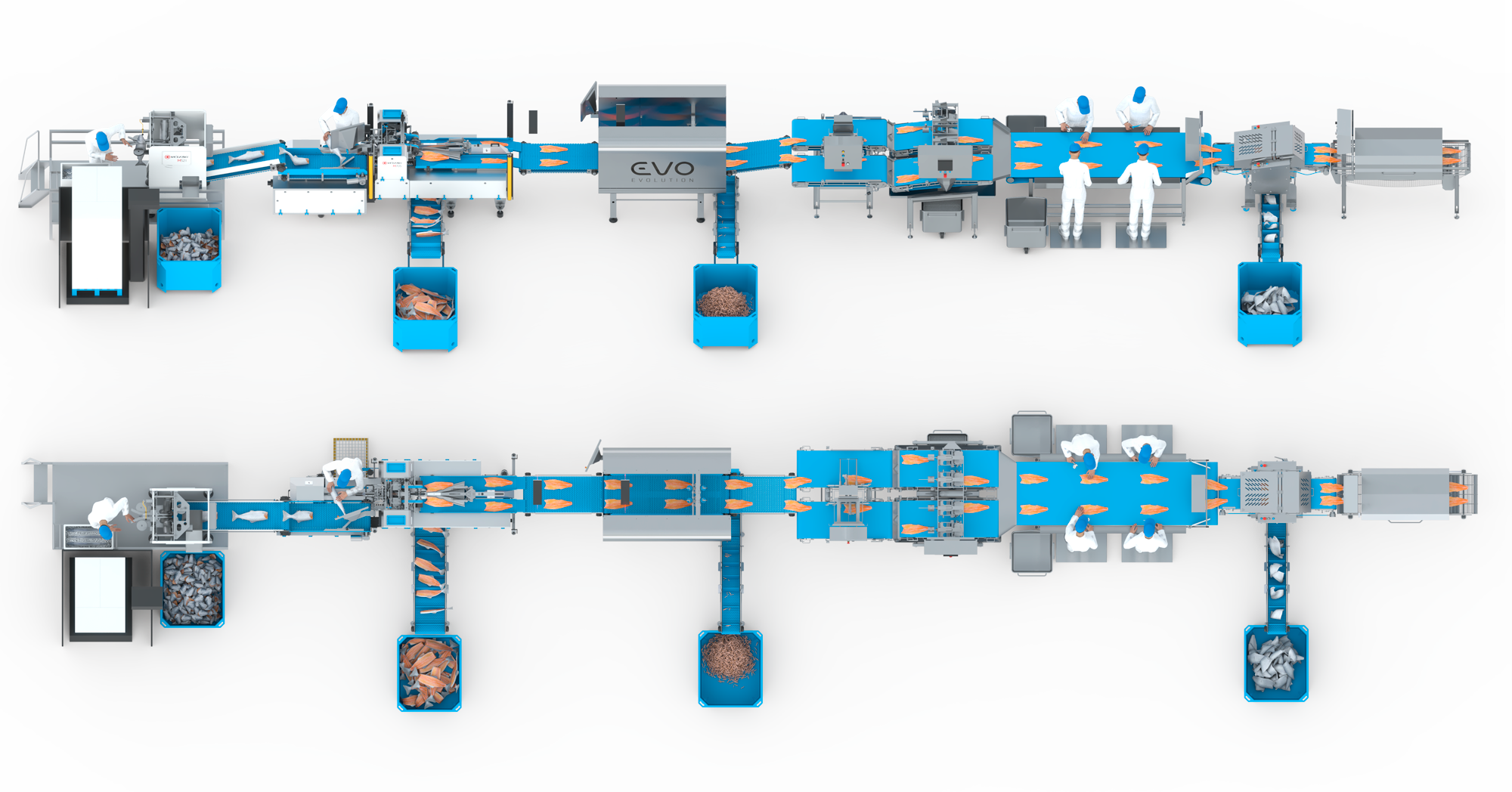

THE PROCESS

Vélfag Salmon Processing Workflow

Deheading

Gutted salmon are fed into the deheading machine, where heads and collarbones are removed with high precision.

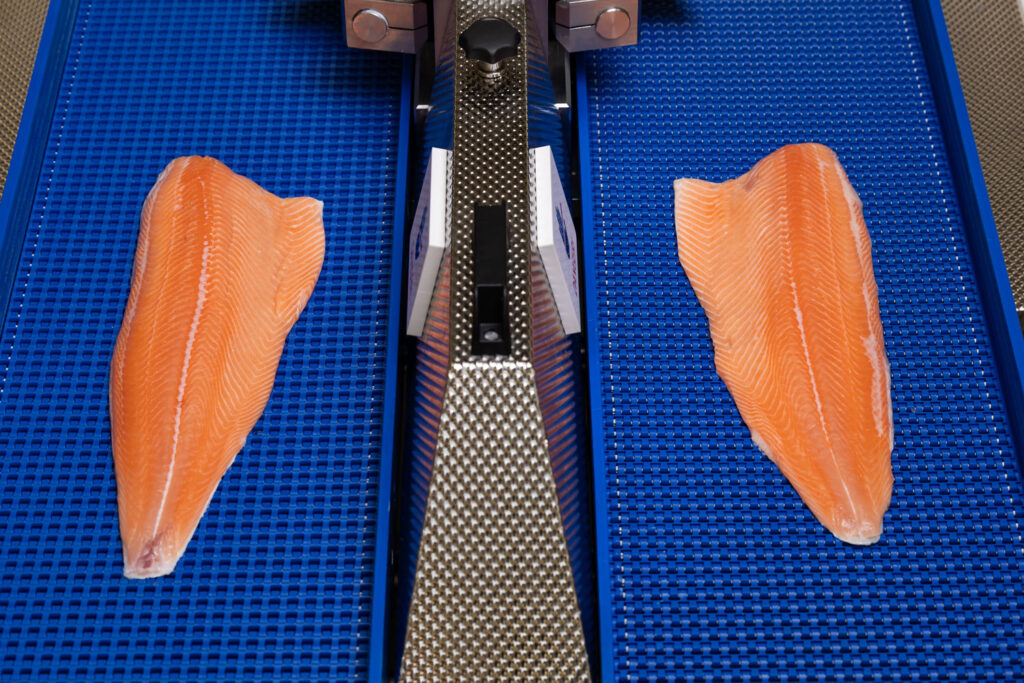

Filleting

Deheaded salmon are filleted using a high-precision system that ensures consistent cuts and high yield.

3D Scanning

Fillets are scanned and analyzed by a 3D vision system to assess shape and dimensions for accurate trimming.

Automatic Trimming

Fillets are trimmed automatically according to predefined specifications, optimizing quality and appearance.

Pinbone Removal

Pinbones are extracted using a fully automated, multi-lane pinbone removal system designed for speed and efficiency.

Trimming & Inspection

Manual trimming and quality checks are carried out to ensure each fillet meets premium product standards.

Deep Skinning

Fillets undergo deep skinning using advanced machines that remove skin and fatty tissue while preserving structure.

Fillet Washing

The process concludes with a thorough rinse in the washing unit, ensuring clean, ready-to-pack fillets.

A clean cut from day one.

Our first trial run delivers impressive results — and we’re just getting started