The Start of a New Technological Era

A Single Solution to Reduce Manpower, Boost Quality, and Enhance Performance for Fish Processing

Innovating the Future of Fish Processing

JUST THE BEGINNING

First operational UNO in the world

Kambur ehf., haddock processing plant of Brim in Iceland, has been important development partner and the first company to implement the UNO fish processing solution from Vélfag. The UNO solution combines three machines into one, and results have been excellent since its installation in Q4 2024.

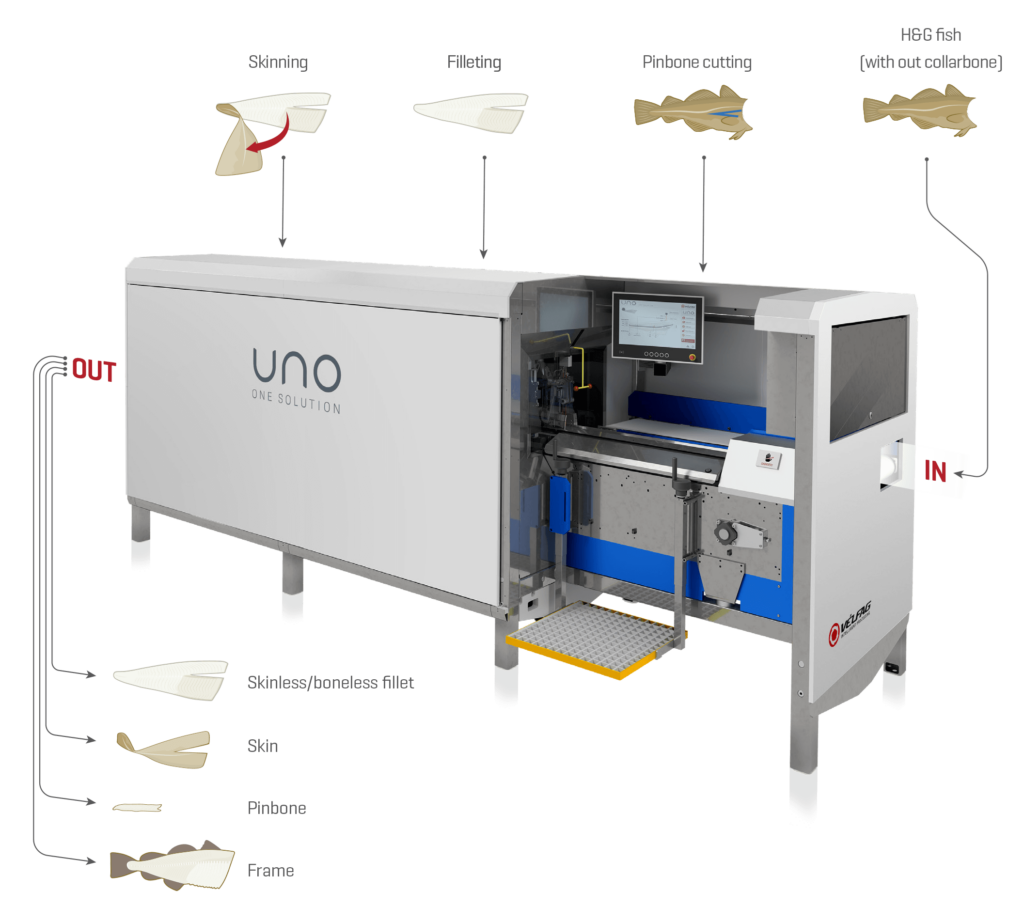

Core version of UNO, processes head off/gutted fish on a saddle, to secure precise and gentle handling through, pin bone removal with high pressure water jet cutting, high yield filleting and gentle skinning, to deliver maximum product quality of fillets and by products. The process secures minimal labor handling and shorter processing, preserving high quality through the process and minimal drip loss. In next phase, a revolutionary heading section will be added, as well as more cutting patterns, to enhance flexibility, handling, yield and efficiency

"This is the future for the Icelandic fishing industry: automation that reduces the number of human hands while increasing quality, speed, and performance. We are extremely pleased with this agreement and proud to be the first Icelandic company to implement this technology, thereby supporting technological progress in the fishing industry”

Hólmar Jóhann Hinriksson – director of the Kambur processing plant

VEL-CUT

VEL-CUT is an advanced technique that increases yield with the pinbone being cut before the filleting process. Not only does VEL-CUT enhance product yield, but it also extends shelf life, ensuring superior quality and longer freshness.

The future is here

Gutted whole fish go in at one end and skinless, bonless fillets emerge at the other

Technical data

Fish Species

Cod, haddock, saithe (pollock), ling, tusk and similar species

Working Range

20-95 cm

Throughput

Up to 45 fish /min – 90 fillets / min

Operation

1 person

Cutting Speed

Adjustable settings on the fly

Water Consumption

Approx 35 L / min total combined

Water Supply Connection

¾ bsp for machine and ½ bsp for water pump

Water Supply

Minimum 3 bar pressure for both machine and pump

Water Pressure

Working pressure approx. 2500 bar (water pump capable of up to 6000 bar)

Air Supply

10mm connection on machine and quick release coupling on pump

Power Consumption

47 kW

Voltage

400-440V

Current Requirement

32A for machine and 80A for pump

Weight

Approx 3935kg total – Machine 3000kg and pump 935kg

Quality of Material

316 Stainless steel.

POM plastics. Antibacterial DuPontTM Corian® for stationary surfaces.

The primary benefit of the UNO machine are

- Replaces up to 5 machines with 1

- Reduces employees by up to 5 workers

- Reduces costs for maintenance and cleaning by at least 3 times

- Reduces production space by at least 3 times

- Reduces the length of conveyors

- Increases product shelf life

- Reduces water consumption by at least 2 times

- Reduces energy consumption by at least 2 times

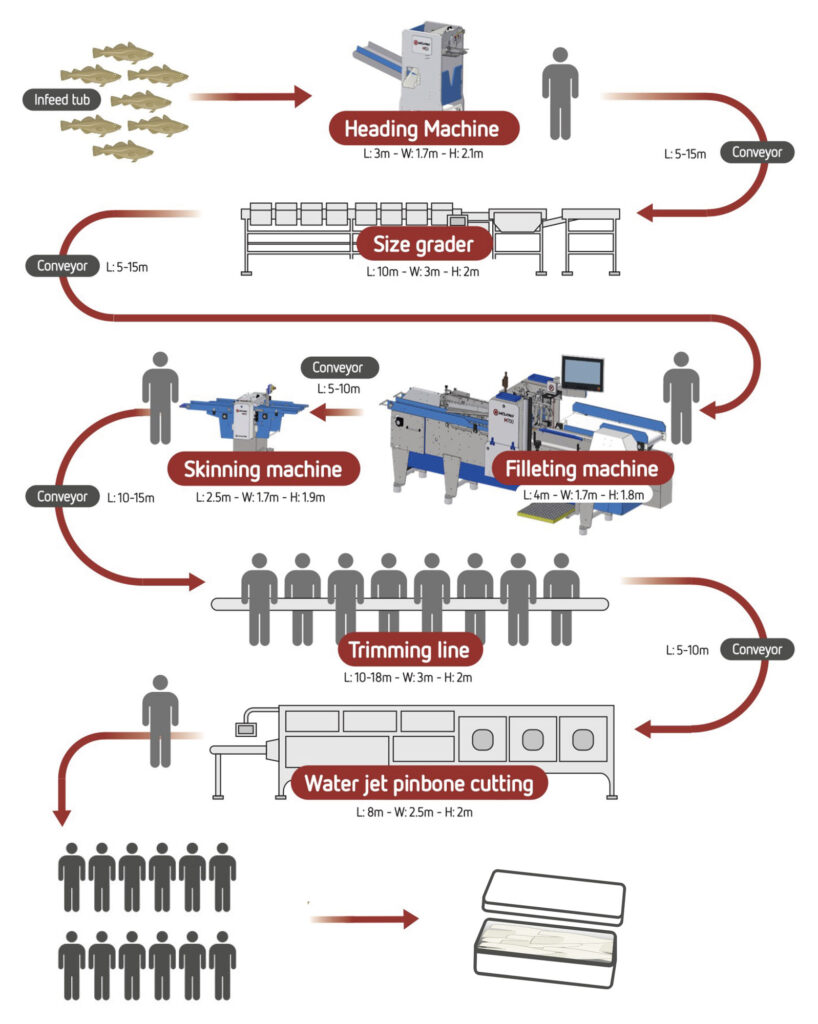

Conventional fish processing line

Velfag’s UNO Machinery Powers the Award-Winning ECOFIVE Trawler

We’re proud to see Velfag’s innovative UNO machinery take center stage in one of the most groundbreaking vessels in the fishing industry. On June 6, 2023, the ECOFIVE factory trawler, developed in collaboration with Bluewild, Ulstein Design & Solutions AS, and Westcon, was awarded Ship of the Year 2023. This honor is a testament to the cutting-edge technology and sustainability embedded in the vessel—technology that is driven by Velfag’s advanced UNO machinery.

UNO Machinery: The Heart of the ECOFIVE’s Processing Efficiency

At the heart of this remarkable vessel are two Velfag’s UNO machinery lines, which is designed to perform multiple key processing functions within a single system. These include heading, filleting, pinbone removal, and skinning, allowing the ECOFIVE to maximize both sustainability and production efficiency. The integration of these processes into one compact, efficient system is a major achievement in the industry and sets the ECOFIVE apart as a trailblazer in sustainable fishing.

Benefits of UNO - One solution

High-Quality Product

The production of high-quality products and by-products, with an extended shelf life due to minimal handling and shorter processing time.

Low Cost of Ownership

Lower production costs through reduced water and energy usage, smaller facility requirements, and decreased maintenance and cleaning needs.

Social Responsibility

The opportunity to process fish in smaller production units, closer to the source of the raw material, within local communities. This reduces transportation needs and lowers the carbon footprint.

Lower maintenance and operational cost

One machine instead of many—reducing overhead, minimizing assembly lines, and lowering spare parts inventory. Fewer people are needed for production, leading to significant cost savings.

Environmentally Friendly Production

Production is environmentally friendly due to reduced water and energy consumption and lower maintenance and cleaning needs. Additionally, a smaller carbon footprint is achieved through less transportation.

Optimized for Space Efficiency

UNO’s compact design maximizes available floor space, eliminating the need for multiple machines and optimizing facility layout for more streamlined operations.

Fourth UNO machinery heads to the world’s largest farmed cod producer!

The fourth UNO fish processing machine from Vélfag has been successfully delivered to ODE, the world’s largest farmed cod producer in Norway. With the latest upgrades, including stainless steel doors and windows for enhanced durability and accessibility, the UNO machine continues to drive operational efficiency and set new standards in fish processing.

“At Ode, we are committed to innovation at every stage of cod farming. Partnering with Vélfag and integrating their cutting-edge UNO technology helps us streamline processing and maximize yield—while also providing a platform for further innovation in byproducts utilisation and value creation.”

— Ola Kvalheim, CEO of Ode